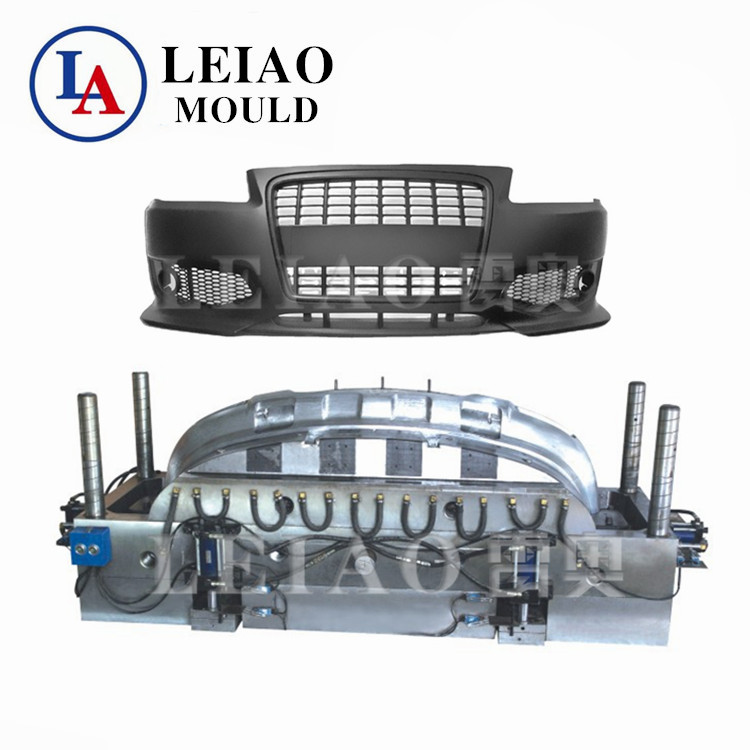

Car Bumper Precision Hot Runner Auto Parts Plastic Injection Mould

Product Description

|

Model NO. |

LA22-118 |

Application |

Car |

|

Runner |

Hot Runner |

Design Software |

UG |

|

Installation |

Fixed |

Certification |

TS16949, ISO |

|

Trademark |

LA |

Customized |

Customized |

|

After-sales Service |

1year |

Transport Package |

Wooden Case |

|

Specification |

2400*1150*1400mm |

HS Code |

8480719090 |

|

Origin |

China, Zhejiang, Taizhou |

Production Capacity |

650 Set/Year |

In the automobile injection mold, for the automobile bumper product, the mold design will usually adopt the advanced inside parting surface technology. The utility model has the advantages that the parting clip line is hidden on the non-appearance surface of the bumper, and the appearance clip line can not be seen after assembly on the automobile, and the appearance of the product can not be affected. However, this kind of technology is more complicated than the outer-parting bumper in terms of difficulty and structure, and the technical risk is also higher. The mold cost and the mold price are also much higher than the outer-parting bumper, but because of the beautiful appearance, it is widely used in medium and high-grade cars. For the automobile bumper plastic parts, generally have the outer type and the inner type two types of classification. For all the car bumper on both sides of the large area of reverse, can be used both outside the type can also be used within the type. The choice of these two types of type mainly depends on the final customer of the car factory to the bumper requirements, the general European and N cars mostly used in the type of technology, Japanese and Korean cars mostly used outside type. The outer-parting bumper needs to deal with the pinch line, which increases the processing procedure, but the outer-parting bumper is lower than the inner-parting bumper in the mould cost and technical difficulty. The inner parting bumper can be perfectly molded by the secondary track control technology, so that the appearance quality of the bumper can be guaranteed and the processing procedure and cost of the plastic parts can be saved. But the drawback is the mold cost is high, mold technical requirements.

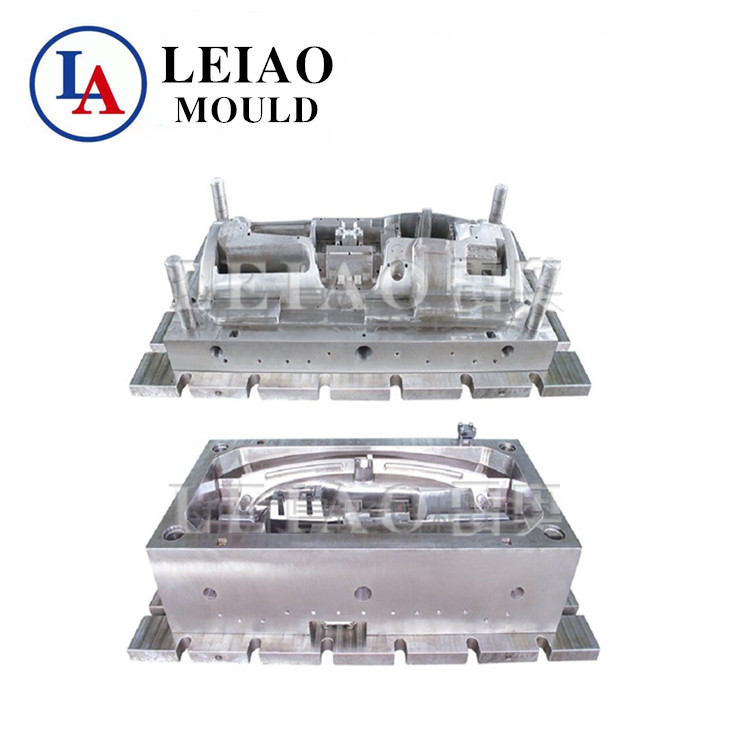

Mold Traits

There are several areas to note when designing and making fan leaf molds.

1

Selection of mold dividing line: it is suggested to extend the middle line of the side of the blade to facilitate mold matching and avoid batch front.

2

Inlet position: It is recommended to set one inlet to each blade to prevent uneven glue filling.

3

Setting of cooling waterway: to be in place, sufficient, to prevent excessive deformation of products.

4

Internal mold processing: this depends on your company's equipment conditions and the selected process flow.

5

Mold assembly: pay attention to the batch front and exhaust.

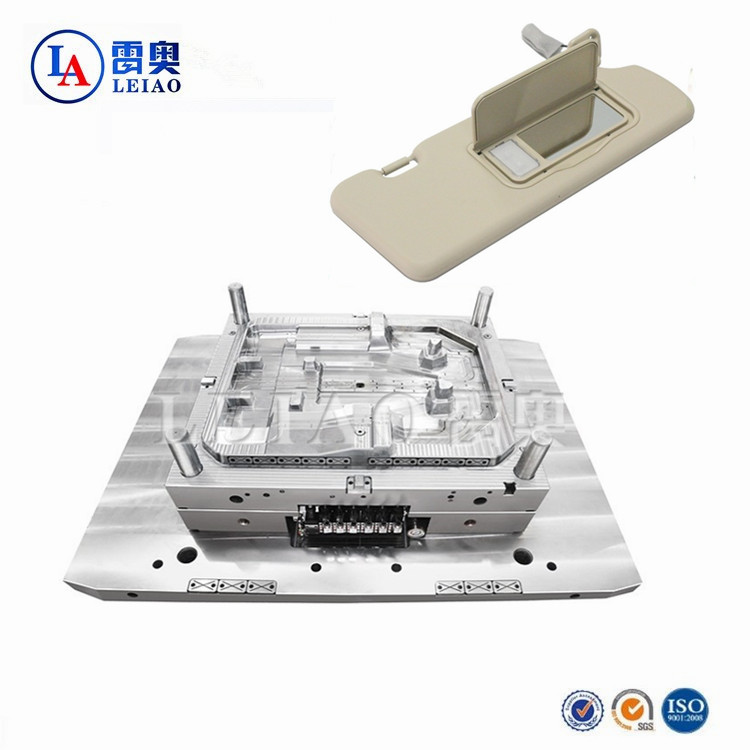

Why choose Leiao Mould for the production of household Mould?

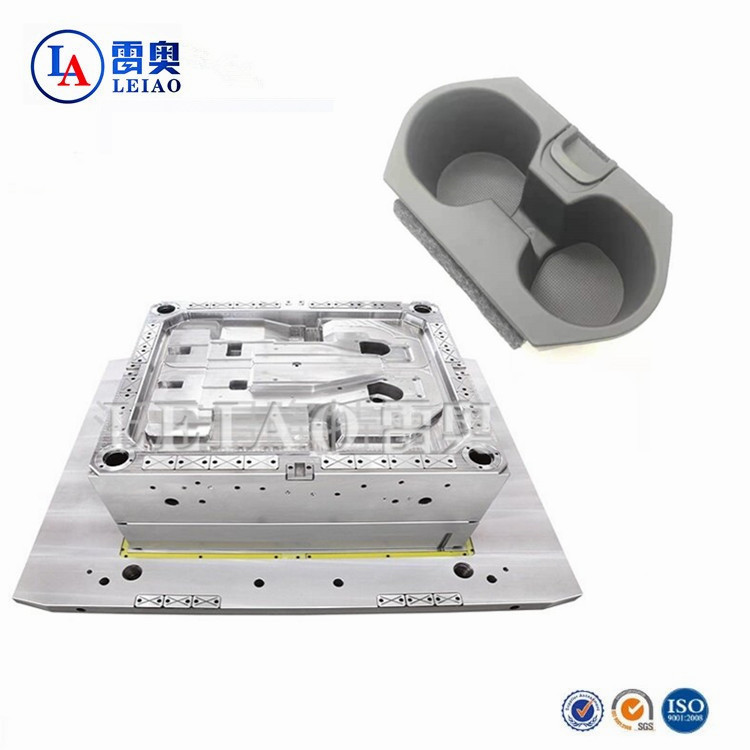

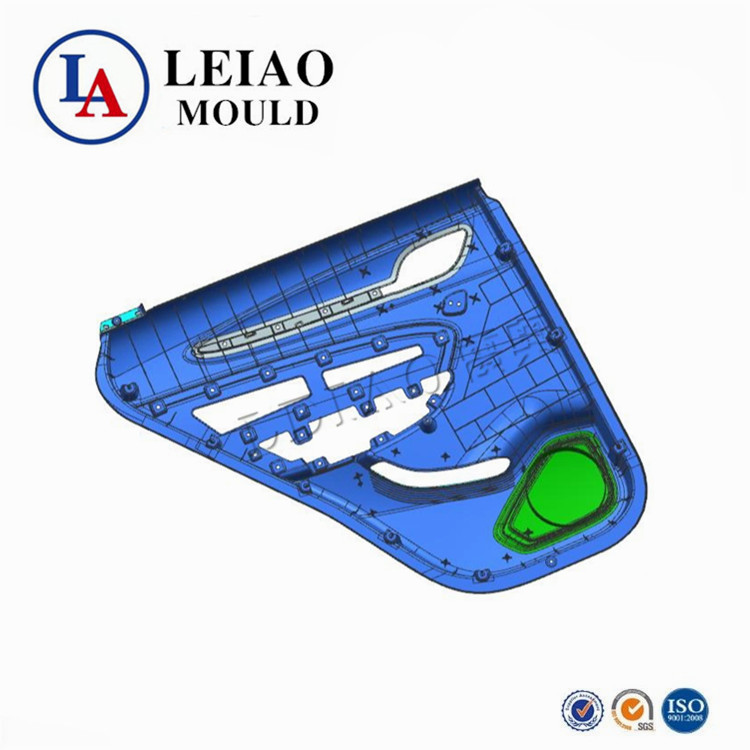

Leiao Mould is a one reliable and professional high quality custom plastic mould manufacturer engaged in mould design,manufacturing & produce a variety of plastic injection moulds.We have a mature team of highly skilled designers, Engineers, Project Managers and Fabrication Technicians that ensure strictly control all of the project success.

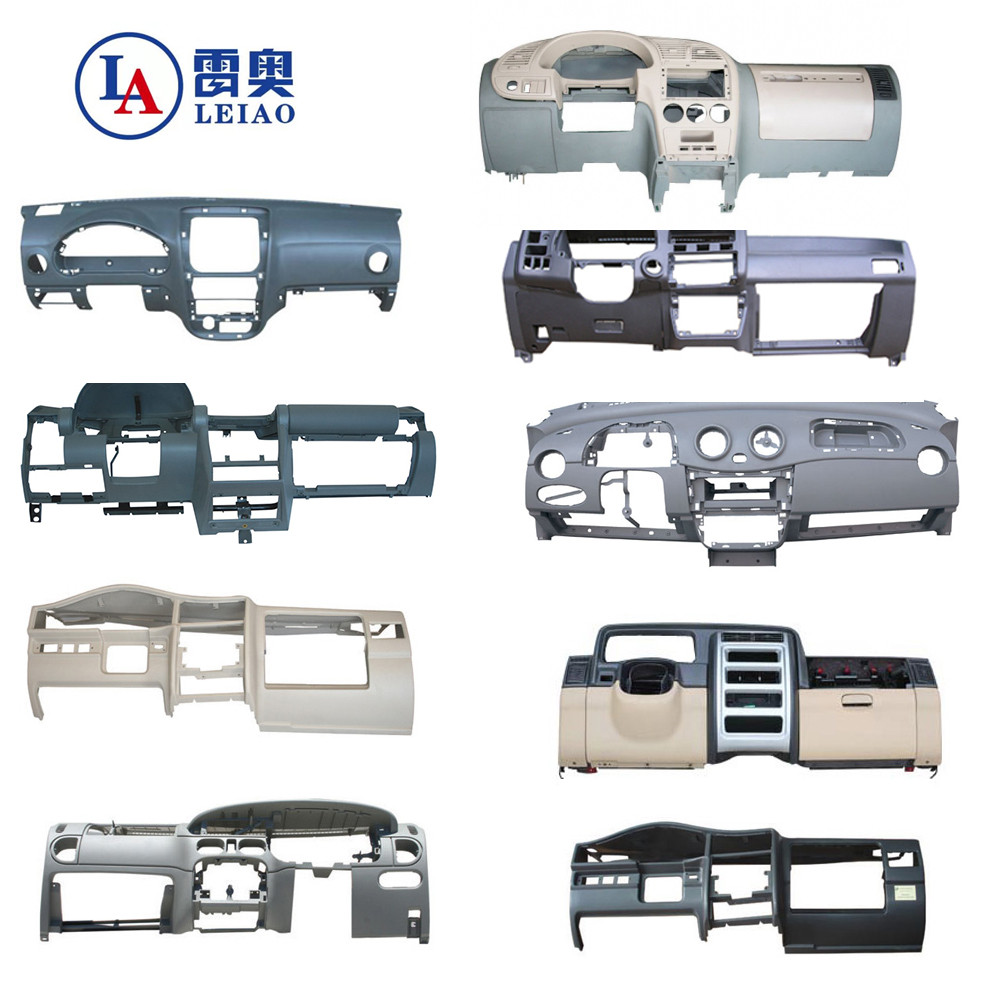

We Specialize in manufacturing all kinds of plastic moulds,such as plastic crate moulds, Car parts mold,plastic pallet moulds,plastic chair moulds, plastic household moulds, plastic Home-appliance moulds, Plastic industries moulds,tableware moulds,etc.