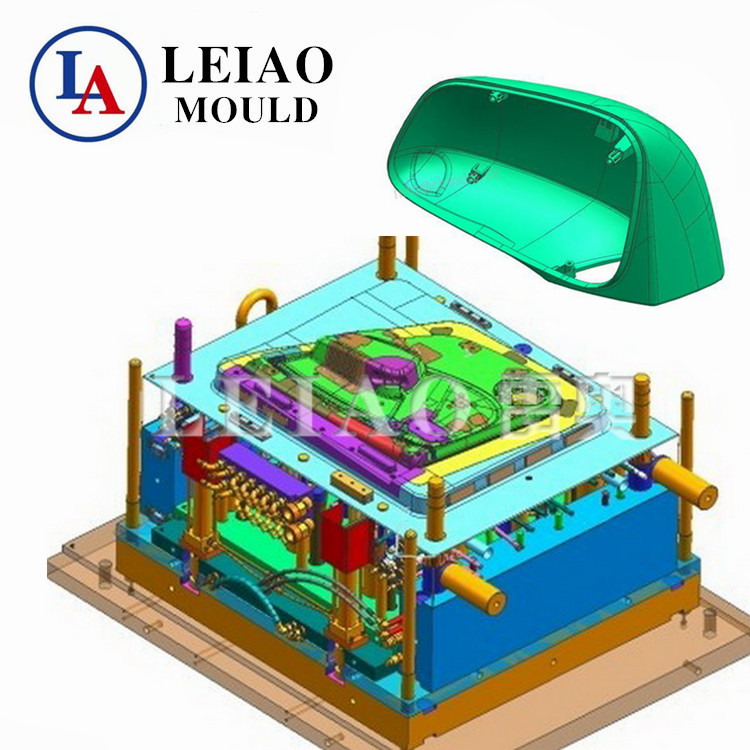

Custom Auto/Car Front Grille Plastic Injection Mould

Product Description

|

Model NO. |

LA22-118 |

Application |

Car |

|

Runner |

Hot Runner/Cold Runner |

Design Software |

UG |

|

Installation |

Fixed |

Certification |

TS16949, ISO |

|

Trademark |

LA |

Customized |

Customized |

|

After-sales Service |

1year |

Transport Package |

Wooden Case |

|

Specification |

2400*1150*1400mm |

HS Code |

8480719090 |

|

Origin |

China, Zhejiang, Taizhou |

Production Capacity |

650 Set/Year |

Grid parting line is more complex, parting surface needs to be designed according to certain rules, not arbitrary, to avoid mold problems, the product grid release angle is usually not large, therefore, in the design according to the requirements of surface treatment for verification. If the product before and after the mold have ribs, need to focus on the verification of the front mold before and after the mold of their release slope generally larger than the rear mold, to avoid the product left before the mold. The grid products have more holes, shape, parting line changes complex, so the mold on the small position more, so, as long as the product allows, the mold as far as possible to use mosaic method, to facilitate processing. For the complex shape grid products, the overall gate layout is considered first, but the weld line is difficult to accurately control. The hot runner system is generally controlled by a sequence raft to adjust the position of the weld line.

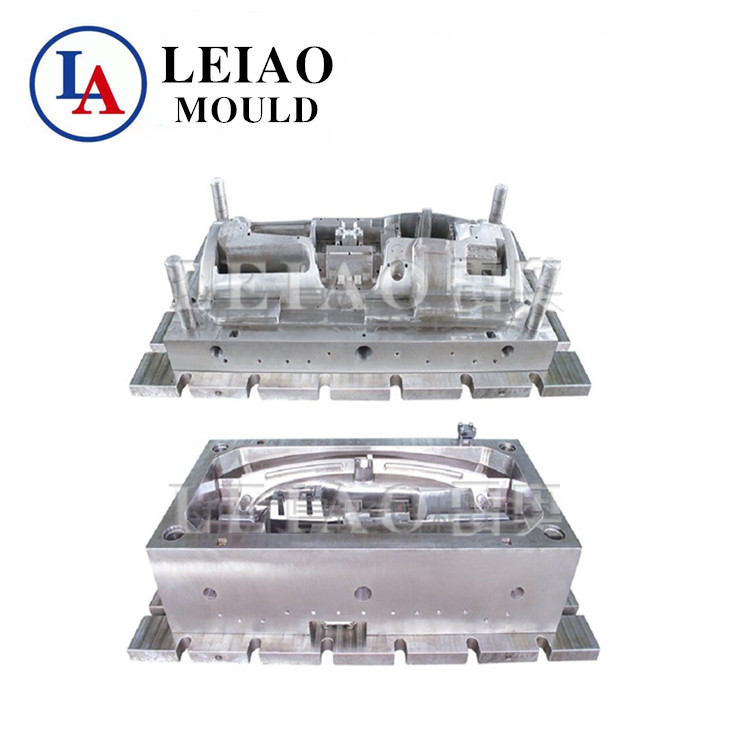

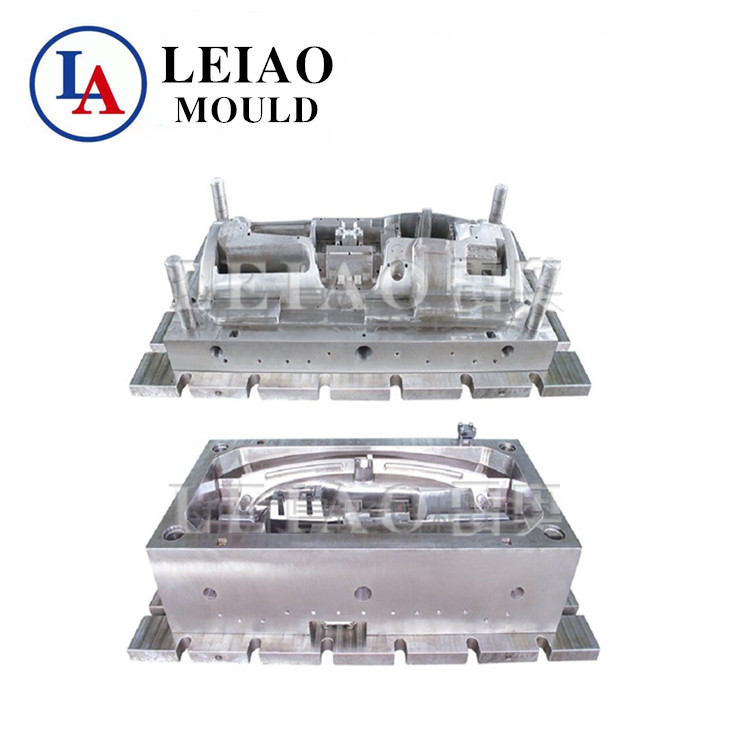

Mold Traits

Car grille mold size is large, the rear mold has more flat top or small diameter thimble, processing is difficult, so it needs to be assembled processing. And has the following advantages:

1

Only the inner mold uses good materials. Lower the overall material costs.

2

The small shapes such as the flat top or small thimble holes on the block are easy for processing

3

NC, EDM and so on can use smaller machine tools, large choice, reduced cost.

Why Choose Leiao Mould For The Production Of Household Mould?

Leiao Mould is a one reliable and professional high quality custom plastic mould manufacturer engaged in mould design,manufacturing & produce a variety of plastic injection moulds.We have a mature team of highly skilled designers, Engineers, Project Managers and Fabrication Technicians that ensure strictly control all of the project success.

We Specialize in manufacturing all kinds of plastic moulds,such as plastic crate moulds, Car parts mold,plastic pallet moulds,plastic chair moulds, plastic household moulds, plastic Home-appliance moulds, Plastic industries moulds,tableware moulds,etc.