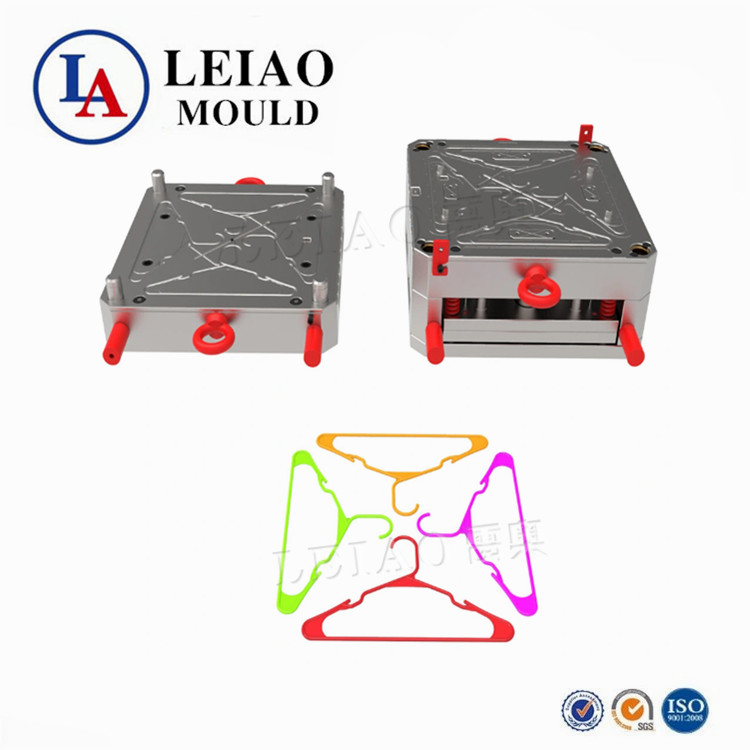

For plastic hanger mold, its production raw materials are mostly PP and PS.In the design, we will design 2 cavity, 4 cavity and 8 cavity according to the production requirements. In large quantities, we will recommend 2+2 and 4+4 laminated molds.The following by Leiao Mould to introduce the advantages of laminated mold.

Laminated mold is a foregoing technology of the development of plastic mold today, which can greatly improve the production efficiency and equipment utilization rate, and can save the production cost and human resources.

Advantages of laminated mould

1) Compared with the conventional die, the clamping force of the laminated die is only increased by 10% ~ 15%, but the output can be increased by 90% ~ 95%;

2) The mould manufacturing requirements are basically the same as the conventional mould, and several pairs of cavities are combined in one mould, so the mould manufacturing cycle is greatly shortened;

3) Using high efficiency laminated injection moulds can double or quadruple the output of ordinary single-layer moulds without the need to invest in additional machinery and equipment.This saves the cost of installing machinery, equipment, expanding the plant and adding labor.

4) the laminated mould can be installed on the injection machine with similar requirements of the single-layer mould, but the output efficiency per unit time is doubled;

5) Save raw materials, easy automation, improve product performance, shorten production cycle.

If you have a demand for hanger mold, welcome to consult and cooperate.

Post time: Jan-22-2024