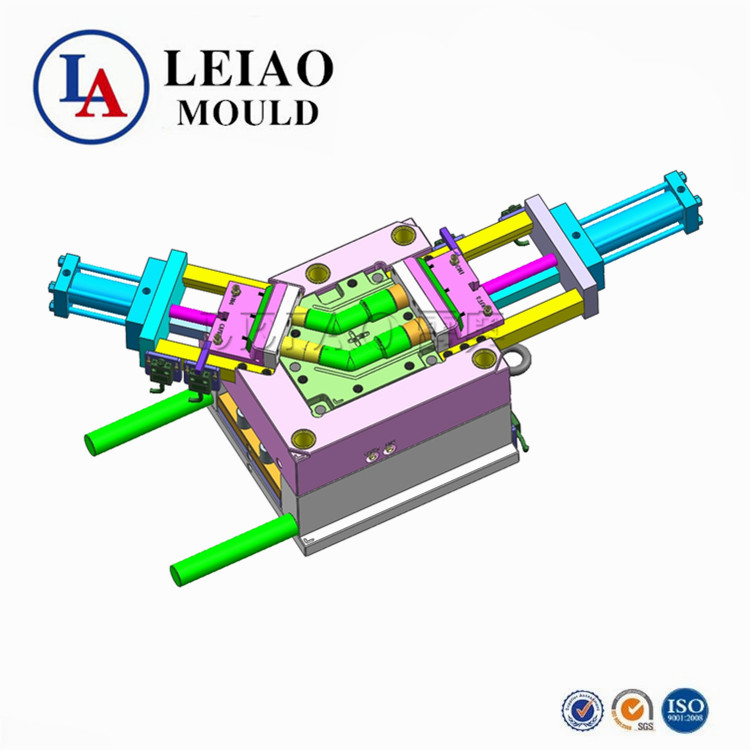

Plastic pipe fittings mold: As the name suggests, it is used to make plastic pipe fittings on the injection molding machine. This model is usually formed by processing and grinding with special steel.

The quality of a plastic pipe mold, mainly depends on the plastic pipe mold production process. Now there are many plastic pipe fittings mold factories, the use of mold steel is different, but really a professional manufacturing plastic pipe fittings mold factory can know how to make their own plastic pipe fittings mold more popular with customers.

The production of plastic pipe fittings mold not only requires a good manufacturing technology, but also requires a perfect modeling structure, the modeling structure and the mold design in the eyes of people who do not understand, but those who really know the mold know that the modeling structure and internal structure design of a mold for a pair of mold importance. The real pipe fittings mold factory is summed up in years of production experience, rather than verbal talk.

1. Generally, if the dosage is large, we strongly suggest that the core, cavity and slider use 718H, 3 cr 13, NAK 80, S136, etc., such a mold can be made with 70-1 million times.

2. If the small amount of mold frame use core, cavity and slider use P20,2738,2316, so that the product can play 500,000 mold.

3.For our customers, the shorter the cycle, the more favorable the market occupation it may bring to them. Different mold manufacturers will take different time to manufacture a pair of pipe fittings mold under the premise of the same quality. Some people think that the longer the cycle may be work the more fine, quality may be better, in fact this is wrong, is because not professional so, so they need longer time to manufacture, because not professional, they need more time to repair, but not the shorter the better, because the whole set of mold manufacturing process takes time. The normal time for a professional mold manufacturer to manufacture a pair of pipe fittings mold is 50 days, but the time can not be less than 35 days, and the time is not more than 65 days. Only the professional production level can make a pair of high-quality plastic pipe fittings mold. Non-professional manufacturers to make products and professional manufacturers to make the mold must be different. Want to open the plastic pipe fittings mold also have to find a professional manufacturer.

4. For the pipe fittings mold, it can be done by many manufacturers. But it does not mean it will do well. No matter what, only professional can make customers trust, as a professional pipe fittings mold factory, in many years of production experience to continue to summarize and explore, now has a complete set of pipe fittings mold design concept and manufacturing process. In the design of every detail is made through careful analysis and certification, in the work is also in the hands of the manufacturer with many years of manufacturing pipe fittings mold. Has been adhering to do professional things, to give customers worry service.

Post time: Apr-01-2023